Production

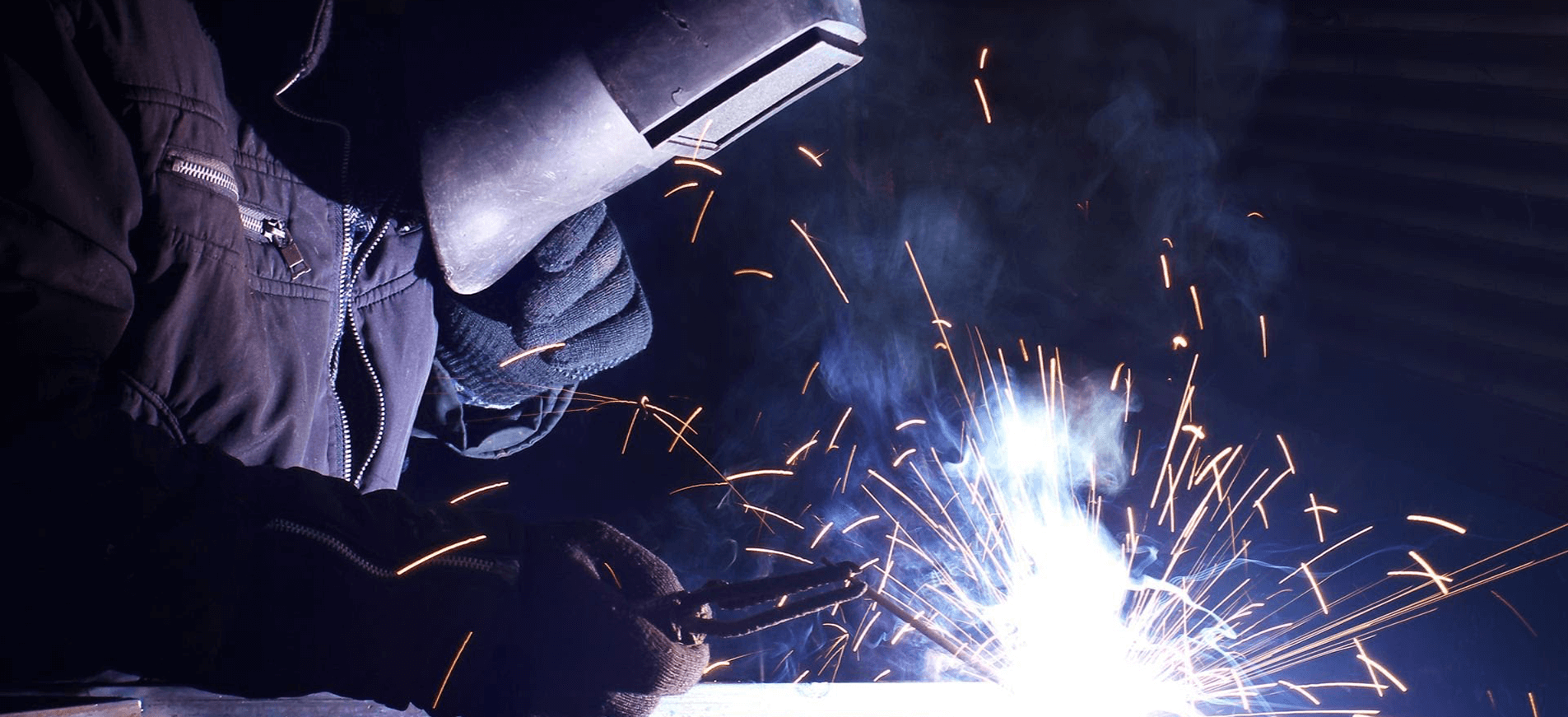

We provide complete production services, working of materials, welding, assembly and servicing. We provide advisory and consultancy activities before planned shutdowns and major repairs, the adjustment of electric motors and valves. We use the TIG welding method. TIG welding may be used to weld all types of metals. In the area of metal processing, we have our own production capacities broken down as follows:

• TIG, MIG technology welding

• Turning work

• Milling operation

• Table shears – cutting

• Production of steel structures

• Assembly work and work at heights

References

Completion of the 3rd and 4th units of Nuclear Power Plant Mochovce

Project description: Supply of fittings

Implementation place: Mochovce – Nuclear Power Plant

Project description: Supply of material for post-assembly cleaning operations at 4th unit EMO 34

Implementation date: 05/2013-08/2016

Implementation place: Mochovce – Nuclear Power Plant

Project description: Supply of material for post-assembly cleaning operations at 4th unit EMO 34

Implementation date: 02/2014-10/2016

Implementation place: Mochovce – Nuclear Power Plant

Project description: Production of piping components for the piping of Mochovce Nuclear Power Plant

Implementation date: 11/2014-06/2016

Implementation place: Mochovce – Nuclear Power Plant

Project description: Production of flow limiters for piping of Mochovce Nuclear Power Plant

Implementation date: 01/2015-06/2016

Implementation place: Mochovce – Nuclear Power Plant

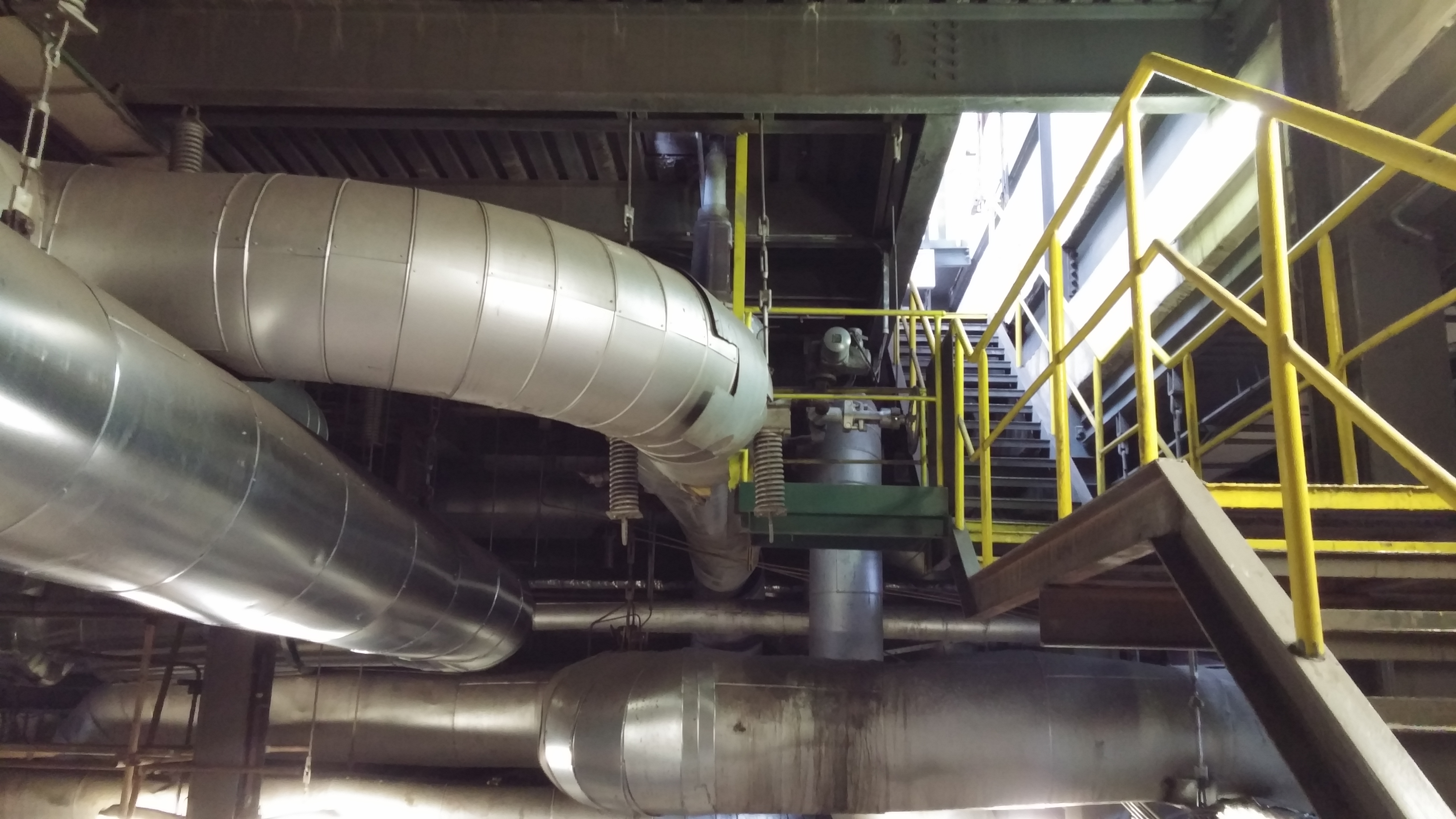

Production site OERLIKON BALZERS Veľká Ida, Slovakia

Project description: Supply and assembly of stainless steel air and water distribution systems. Connection of machinery to the distribution systems.

Implementation: 05/2015 – 06/2015

Supply and assembly of interconnection piping DN 250

Project description: Interconnection piping DN 250

Implementation date: 02/2016

Hotel Partizán – stainless steel hand-rails

Project description: Supply and assembly of stainless steel hand-rails

Implementation date: 12/2015